︎︎︎ Back

SHIFTING PANEL PROTOTYPE

PHILADELPHIA, PA | FALL 2021 | 732 ELECTIVE| CRITIC RICHARD GARBER | TEAM LISA KNUST, LAUREN HANSON, MADISON TOUSAW

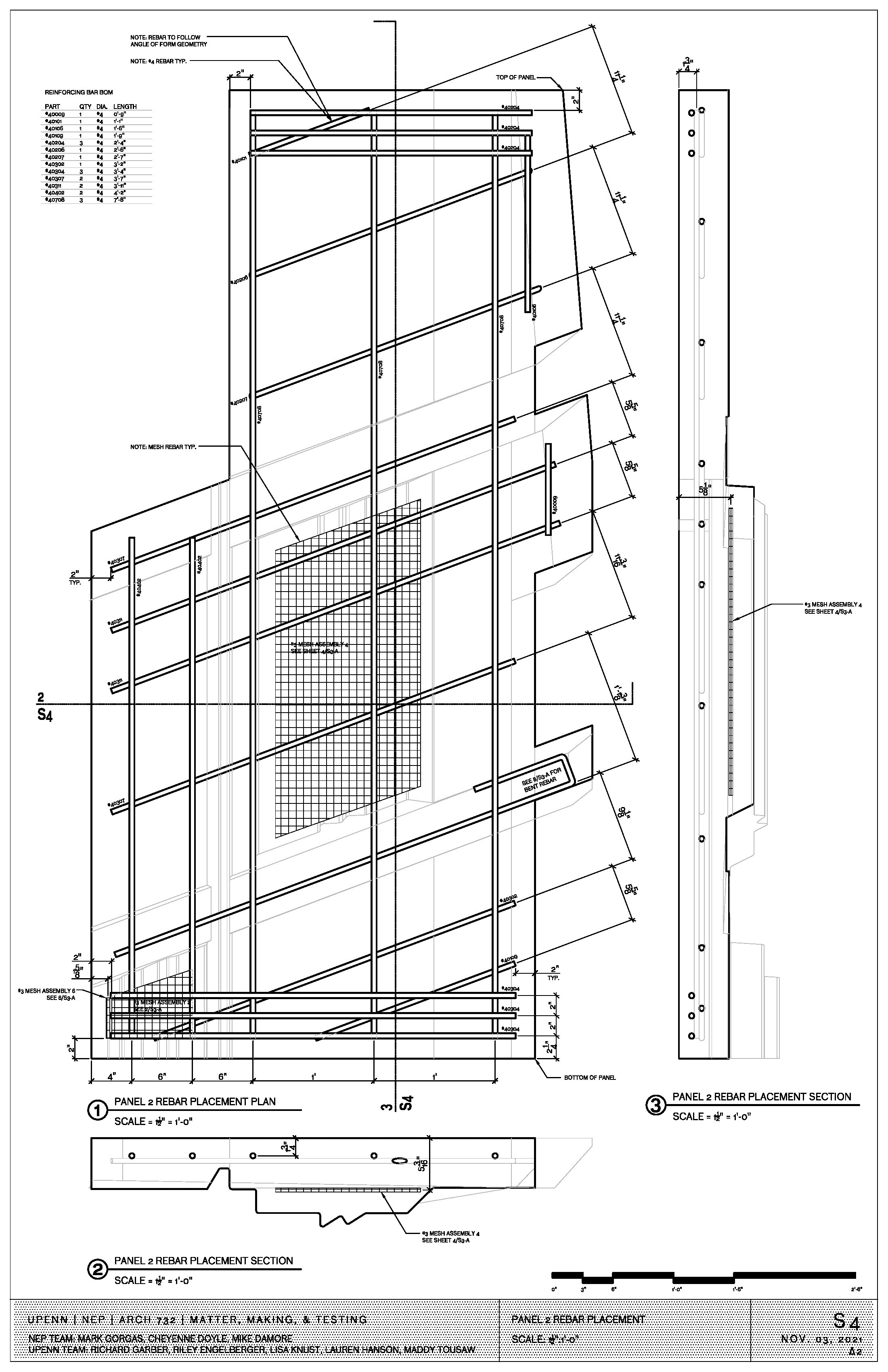

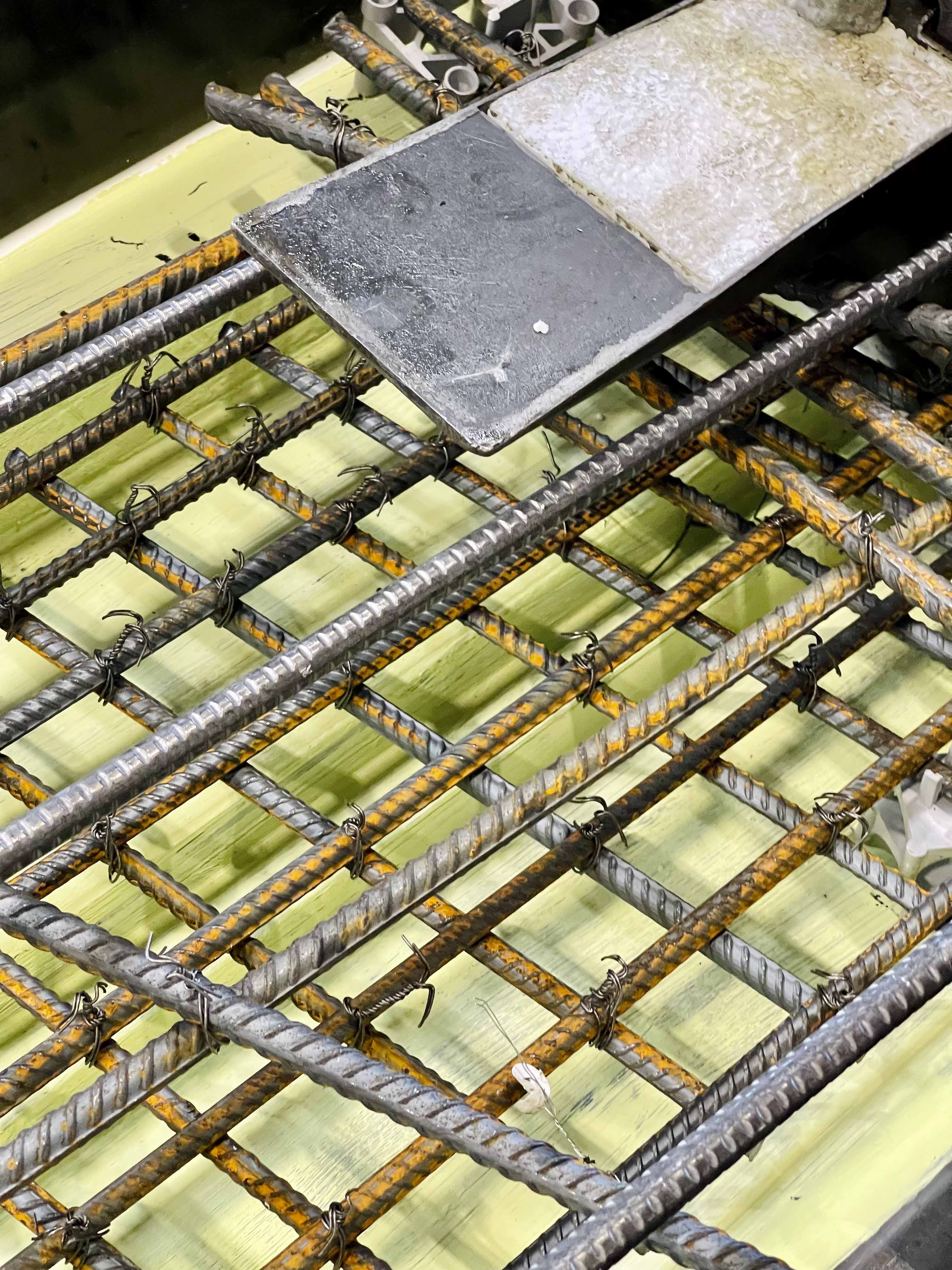

These precast concrete panels are the culmination of a semester-long collaboration with Northeast Precast (NEP), a company located in New Jersey. Our team designed the panels and with assistance from NEP, fabricated stainless steel formwork, and poured two panels.

A primary goal for the course was to fabricate a single formwork of stainless steel that could be re-used for the production multiple panels that formed a corner connection and were different. Our team accomplished these goals by designing an interlocking edge condition such that when one panel was formed and erected, the second panel that came out of the same formwork could be simply rotated in such a way as to slot them together at the corner. To introduce variation within a single formwork, foam blockouts are created and inserted to block off zones of the form.

This is one of my favorite projects because I had the opportunity to design, draw, and fabricate the final product at scale - each of these panels is 4’ x 8’ and would in theory clad a building.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

︎︎︎ Back

SHIFTING PANEL PROTOTYPE

PHILADELPHIA, PA | FALL 2021 | 732 ELECTIVE| CRITIC RICHARD GARBER | TEAM LISA KNUST, LAUREN HANSON, MADISON TOUSAW

These precast concrete panels are the culmination of a semester-long collaboration with Northeast Precast (NEP), a company located in New Jersey. Our team designed the panels and with assistance from NEP, fabricated stainless steel formwork, and poured two panels.

A primary goal for the course was to fabricate a single formwork of stainless steel that could be re-used for the production multiple panels that formed a corner connection and were different. Our team accomplished these goals by designing an interlocking edge condition such that when one panel was formed and erected, the second panel that came out of the same formwork could be simply rotated in such a way as to slot them together at the corner. To introduce variation within a single formwork, foam blockouts are created and inserted to block off zones of the form.

This is one of my favorite projects because I had the opportunity to design, draw, and fabricate the final product at scale - each of these panels is 4’ x 8’ and would in theory clad a building.

SHIFTING PANEL PROTOTYPE

PHILADELPHIA, PA | FALL 2021 | 732 ELECTIVE| CRITIC RICHARD GARBER | TEAM LISA KNUST, LAUREN HANSON, MADISON TOUSAW

These precast concrete panels are the culmination of a semester-long collaboration with Northeast Precast (NEP), a company located in New Jersey. Our team designed the panels and with assistance from NEP, fabricated stainless steel formwork, and poured two panels.

A primary goal for the course was to fabricate a single formwork of stainless steel that could be re-used for the production multiple panels that formed a corner connection and were different. Our team accomplished these goals by designing an interlocking edge condition such that when one panel was formed and erected, the second panel that came out of the same formwork could be simply rotated in such a way as to slot them together at the corner. To introduce variation within a single formwork, foam blockouts are created and inserted to block off zones of the form.

This is one of my favorite projects because I had the opportunity to design, draw, and fabricate the final product at scale - each of these panels is 4’ x 8’ and would in theory clad a building.